Rising demand for sustainable-sourced consumer products, fueled by population growth and increasingly eco-conscious, impact-driven consumers has proven too much for the legacy Contract Manufacturing Organization (CMO) industry.

Built primarily for pharmaceuticals, the CMO industry is aged, innovation constrained, and cannot efficiently produce at the cost or scale to achieve profitability for novel biotechnology ventures or downstream price parity for consumers. This issue drives an unsustainable price and quality matrix for the future of biotechnology.

By 2035, Liberation Labs conservatively estimates a 10x increase in demand, almost 600 million liters of fermentation capacity.

Estimated to be at least 90 million liters. 50% more than current CMO capacity.

Less than 10% of existing CMO capacity fit for food production.

Strategically designed and engineered with your needs in mind, Liberation Labs’ efficient and flexible fermentation process is the competitive advantage for biomanufacturing due to its integration of:

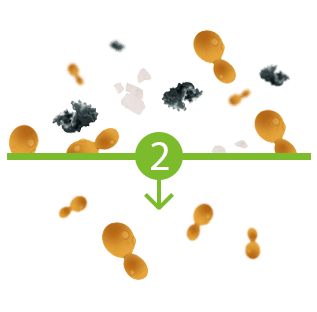

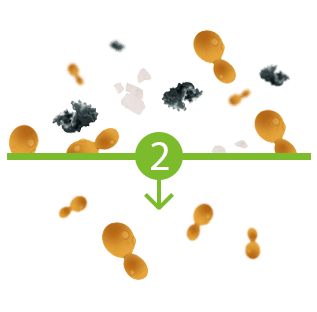

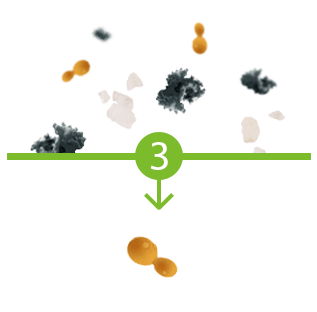

Cell mass removal

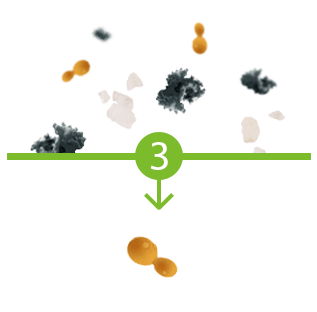

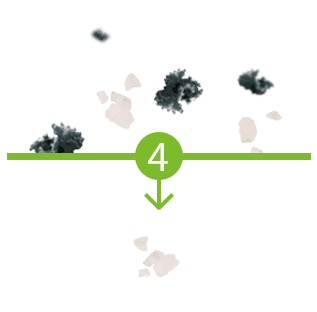

Polishing filtration

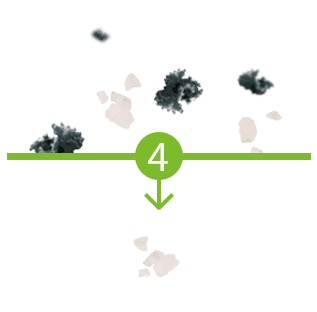

Retain proteins while removing salts

Shelf stable dry product

Strategically designed and engineered with your needs in mind, Liberation Labs’ efficient and flexible fermentation process is the competitive advantage for novel food ventures due to its integration of:

Cell mass removal

Polishing filtration

Retain proteins while removing salts

Shelf stable dry product

Liberation Labs is currently open to customer inquiries, new team members, and investment discussions.

© 2022 Liberation Labs. All rights reserved.

Liberation Labs Holdings, Inc.SM , BIO3 SM , BIO3[DESIGN, BUILD, OPERATE] SM , and all related service names, design marks, and slogans are service marks of Liberation Labs.